In the globe of electronics and contemporary technology, the importance of printed circuit boards (PCBs) can not be overstated. A PCB, usually referred to as a circuit board, gives the essential framework for attaching different electronic elements with conductive tracks engraved onto non-conductive substratums. Amongst the lots of types of PCBs, the rigid-flex circuit boards stand out as an exceptional advancement.

The production of PCBs, particularly in high-density interconnect (HDI) setups, has actually progressed as the demand for smaller, much faster, and a lot more effective electronics increases. HDI PCBs incorporate finer lines and rooms, in addition to smaller vias, which permit higher component density. This is specifically vital in today's hectic tech landscape where efficiency enhancements are continually sought. To manufacture these innovative boards, companies typically use advanced techniques such as microvia innovation, which involves producing very little vias through laser drilling approaches. The benefits of microvias consist of enhanced signal speed and lowered electromagnetic disturbance, consequently improving the overall capability of the electronic gadgets they sustain.

Collaborative ventures with printed circuit manufacturers are essential in ensuring that PCB designs change efficiently from theoretical stages to real products. Printed circuit board assembly (PCBA) becomes a vital action in the process where different components are soldered onto the PCB in precise setups to ensure optimum procedure.

Quick turnaround PCB prototyping services have obtained appeal as companies strive to bring their products to market swiftly. This nimble manufacturing approach permits companies to evaluate and confirm their styles prior to dedicating to complete production runs. Such prototyping is important in minimizing time-to-market and permits repetitive improvements based upon initial testing results. Suppliers use flexible options for both high-volume and low-volume orders to fit varied manufacturing needs. In addition, with the enhancing accessibility of fast-turn PCB services, the barriers to prototype growth have been dramatically lowered, allowing an environment of development.

Flexible printed circuit boards (FPCBs) are an additional amazing category that has actually gathered focus due to their special capabilities. These boards are made to be ultra-thin and lightweight, providing the capacity to flex, fold up, or twist without jeopardizing performance.

Thermal monitoring, for circumstances, plays a crucial role in PCB design, especially in electronic products that operate under high lots. Designers have to take into consideration products with excellent thermal conductivity, such as heavy copper PCBs, which aid dissipate warmth efficiently.

Understanding regarding various facets such as circuit card assembly, which includes the process of soldering parts onto a PCB, can substantially impact the end product's quality. In addition, using devices and software application designed for PCB design and simulation can dramatically enhance the design process, permitting developers to swiftly alter prototypes based on testing end results.

Variations in PCB types such as 2-layer, 4-layer, and multi-layer boards are each matched to specific applications based on their complexity and the number of parts that require to be integrated. Four-layer PCBs supply raised routing abilities, vital for much more advanced electronics. These boards aid in managing signal integrity and offer adequate room to route traces more efficiently, making certain even more trustworthy efficiency in everything from smartphones to complex industrial equipment.

Contract PCB assembly services have become a crucial resource for companies lacking the custom pcbs in-house capacities to handle complex assembly processes. These services often include comprehensive assistance varying from design consultation to full-scale production, providing organizations with the adaptability they require to satisfy varying demands. By partnering with well established manufacturers, companies can leverage know-how in locations such as HDI designs, microvias, and multilayer PCBs, click here thus expanding their item offerings without spending heavily in equipment and labor.

Selecting the best materials for PCB production is critical, and factors to consider commonly include the environmental criteria suitable to their usage, including UL rankings, such as 94V-0, which relates to fire retardancy. Manufacturers require to remain informed concerning conformity regulations to make sure that their items meet safety and security requirements while also executing efficiently in their desired application atmospheres.

The integration of superhigh frequency (RF) innovation into PCBs is one more area seeing boosted relevance, especially with the surge of wireless interaction devices. RF PCBs should be carefully made, with considerations for insusceptibility control and reduced signal loss as a result of the high frequencies included. This field of expertise requires understanding of RF circuit design and might involve in-depth electromagnetic simulations as engineers function to achieve ideal capability in compact types.

As technology remains to develop, manufacturers are progressively taking on automation and advanced fabrication processes to improve performance. Technologies such as automated optical inspection (AOI) and surface install technology (SMT) are now common techniques, allowing for high-speed assembly and consistent high quality control. Advancements in PCB manufacturing likewise include brand-new products and methods, such as the usage of ingrained modern check here technology where components are ingrained straight within the layers of the PCB, better conserving room and boosting efficiency.

To conclude, the printed circuit board sector consistently adjusts to transforming needs and technological developments, reflecting the dynamic landscape of electronics. Whether via PCBA, flexible circuits, or fast-turn prototypes, the materials, procedures, and styles connected with PCBs are critical in forming the future of electronic gadgets. Manufacturers who stay at the leading edge of these developments not just boost their one-upmanship yet likewise enable the development and growth of innovative innovations that define modern life. With the ever-increasing intricacy of circuits and the need for reliable, high-performance options, the PCB industry remains a cornerstone of technological development, driving the way we interact with tools and ultimately attaching our digital and physical globes.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Haley Joel Osment Then & Now!

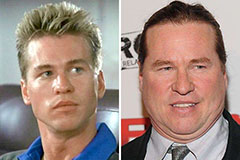

Haley Joel Osment Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now!